Customer Support

Frequently Asked Questions

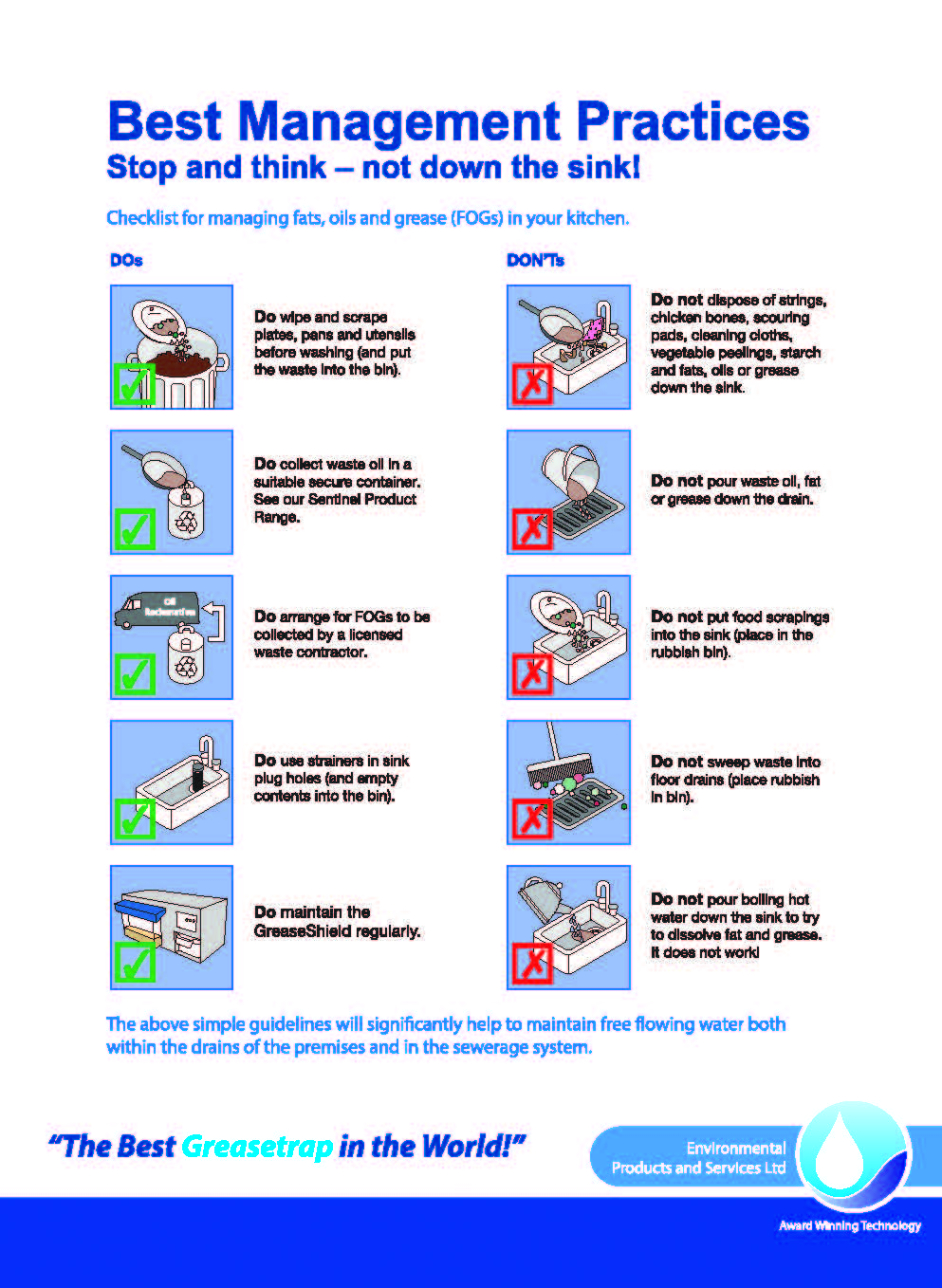

Fats, oils, and grease (FOG) typically come from a variety of sources, including:

1. Cooking: Fats and oils used in cooking, frying, baking, and grilling can easily become FOG when they cool and solidify.

2. Food waste: Leftover food scraps that contain fats and oils can contribute to FOG buildup when washed down drains.

3. Meat products: Fatty meats, such as bacon, sausage, and beef, can release fats when cooked and washed.

4. Dairy products: Butter, cheese, milk, and other dairy items can contain fats that contribute to FOG when washed down drains.

5. Sauces and dressings: Salad dressings, gravies, mayonnaise, and other condiments often contain oils and fats that can solidify in pipes.

6. Food processing: Food manufacturing facilities can produce significant amounts of FOG as a byproduct of their operations.

FOG can accumulate in sewer systems and cause blockages and backups if not properly managed. It’s important for individuals and businesses to dispose of FOG responsibly, such as by collecting it in grease traps or interceptors and disposing of it properly rather than pouring it down drains.

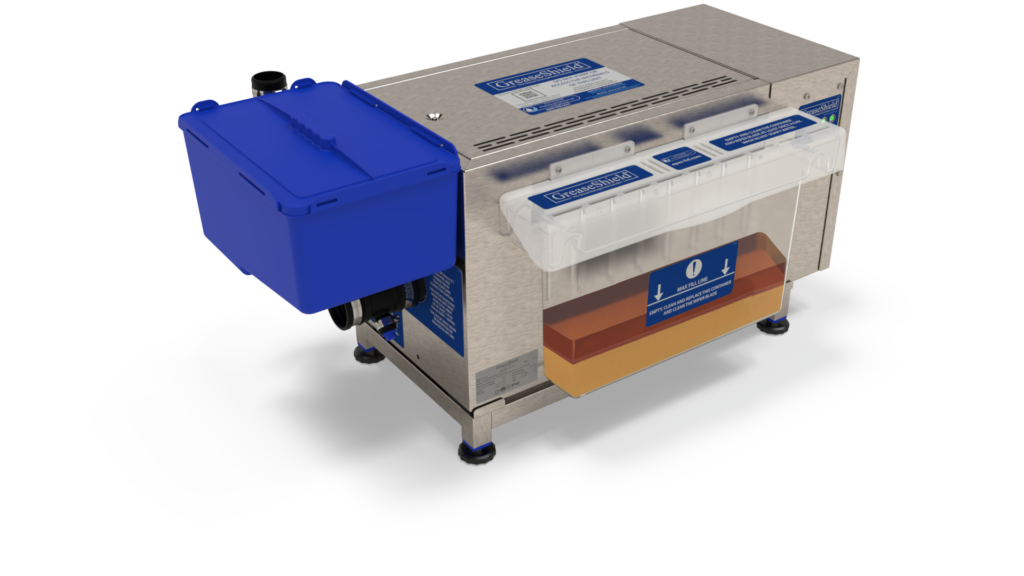

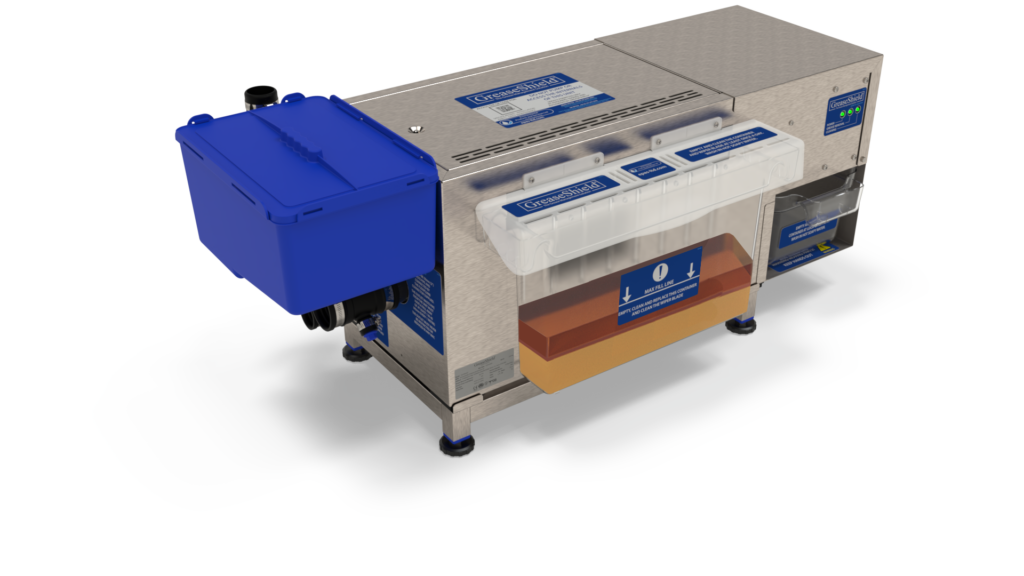

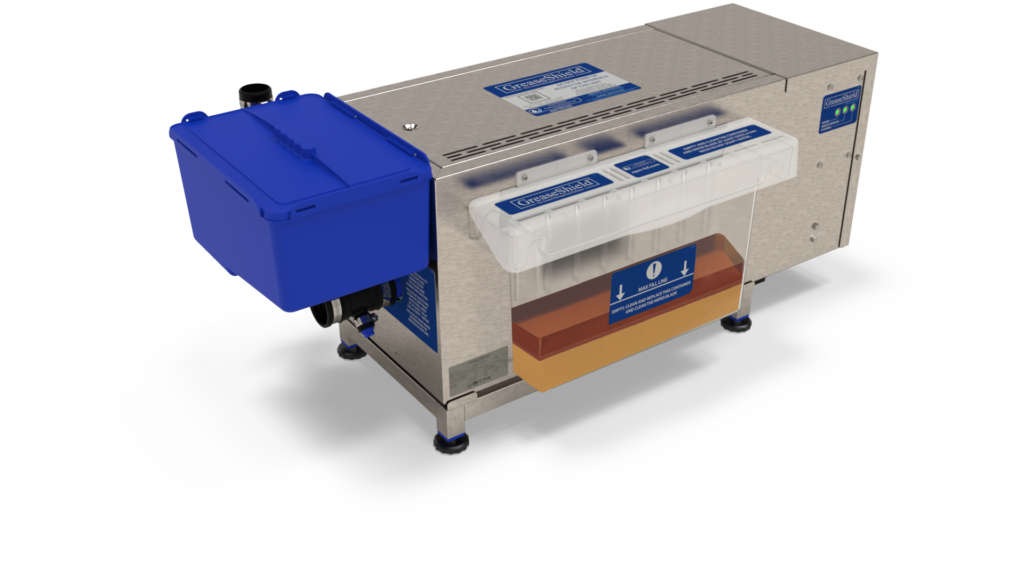

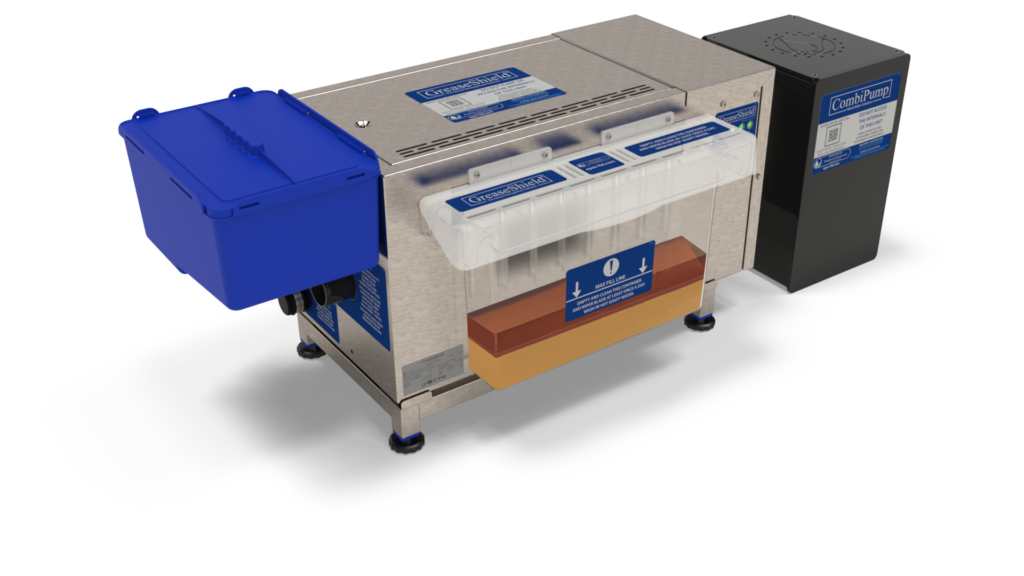

Food waste solids and FOG are eliminated by GreaseShield® in four steps:

- Food Solids Removal: As wastewater enters the unit, an auger or pre-filter screens and dewaters the food solids, which are subsequently placed in an external container.

- Grease Separation: Baffles, reverse flow, and thermal layers are used to separate FOG using waste heat energy prior to its solidification.

- FOG Removal: Oil is drawn to and extracted by a semi-submerged oleophilic roller, which is then scraped off and transferred into an external container for disposal.

- Self-Cleaning: The device reuses grey water to eliminate sedimentation, reducing standing water and unpleasant aromas. It also does routine internal washdowns and circulation pump activations.

A constant, maintenance-free functioning and optimal kitchen efficiency are guaranteed by this effective method.

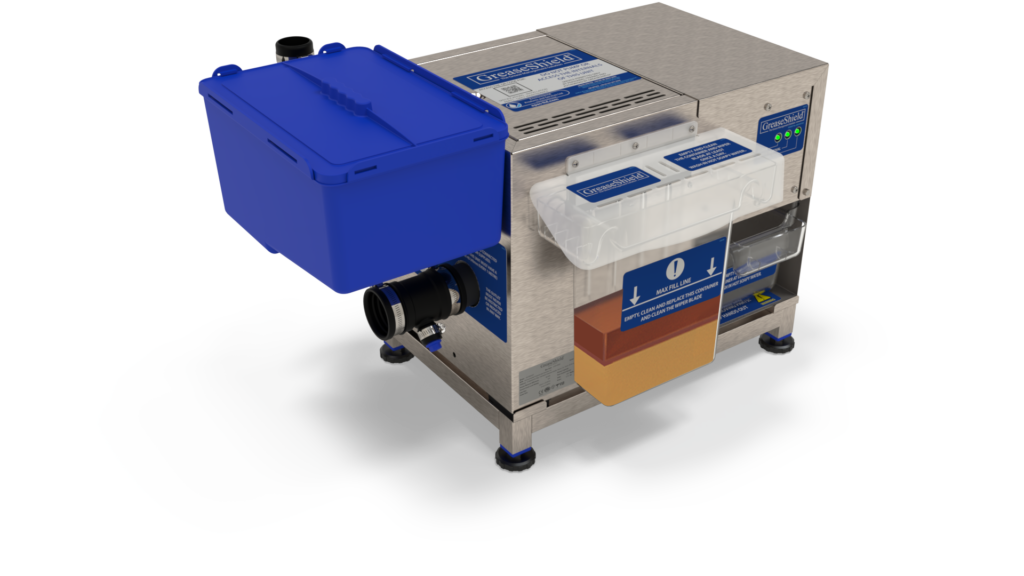

GreaseShield® can be placed in a range of kitchen configurations, from compact prep sinks to larger spaces with ovens and dishwashers. It needs to be mounted above ground, preferably next to linked appliances or beneath the sink, and 1.5 meters away from a dedicated 5 amp power outlet.

GreaseShield® is made to last; after 10 years, some units are still in use. There is a 10-year guarantee on the stainless-steel cabinet (excluding purposeful and unintentional damage). It is advised to have quarterly maintenance procedures performed to guarantee longevity and peak performance. For efficient and routine maintenance, EPAS provides a managed service package. Upgrade options are available for inoperable or outdated systems.

Some local authorities such as Dublin county council require grease traps/interceptors to be serviced and maintained every quarter. In this case, EPAS can offer competitive quarterly preventative maintenance which will ensure that the GreaseShield® is maintained by the local authority guidelines and is working efficiently and effectively.

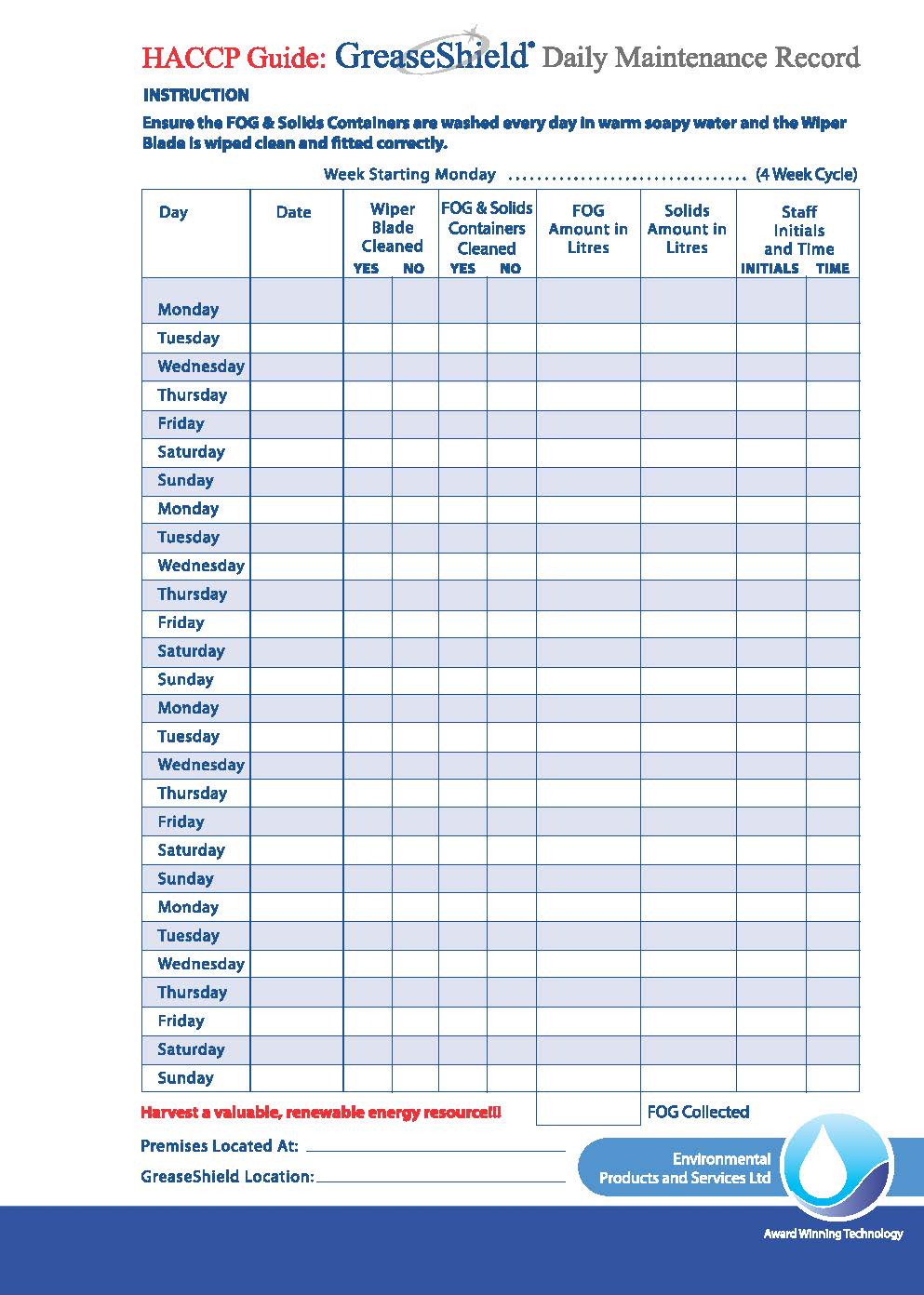

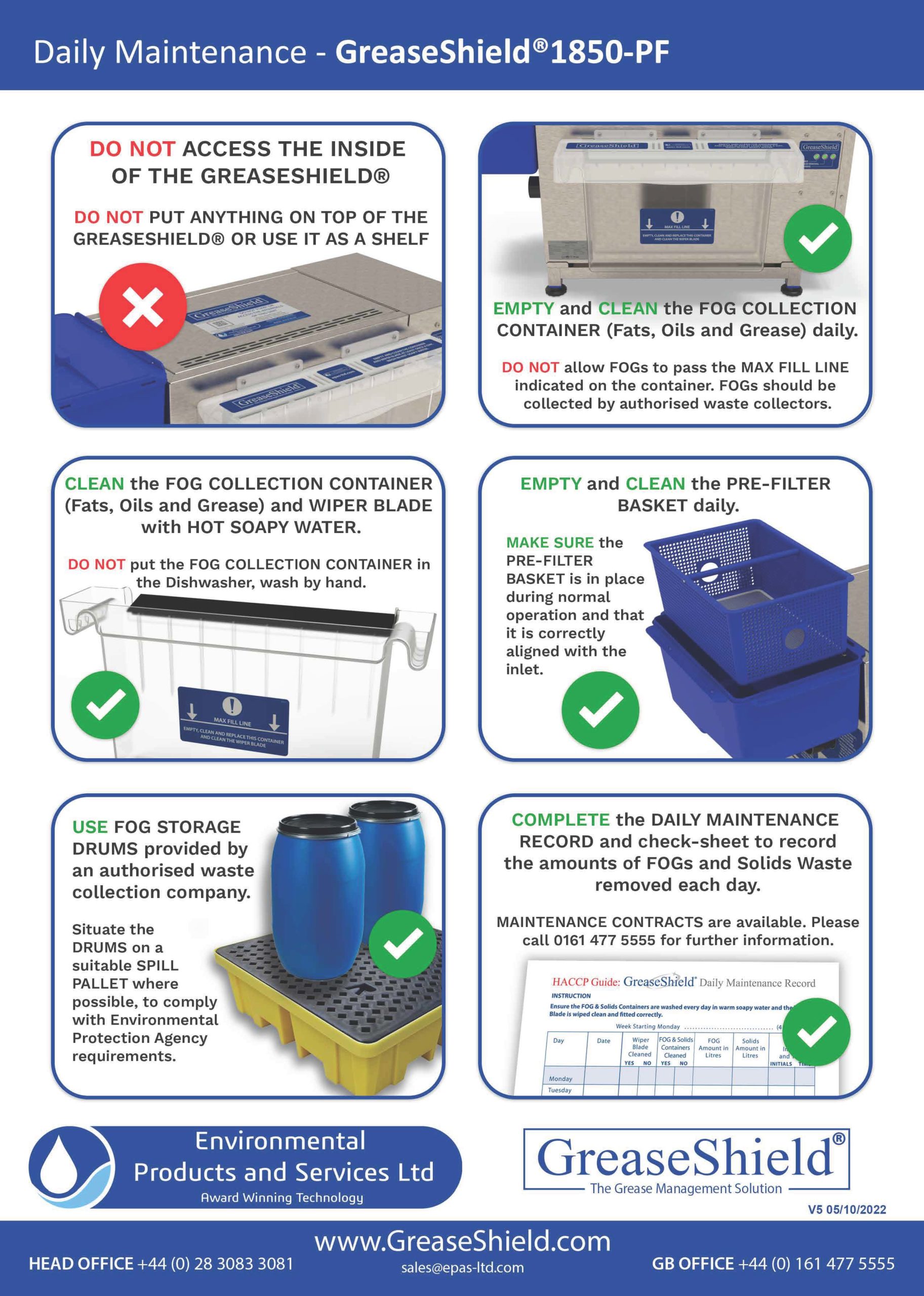

Yes, GreaseShield® requires very little upkeep every day. At the end of the day:

- Take out the food waste basket, empty it, and give it a wash in warm, soapy water.

- Using the included spray pistol, clean the PreFilter or FilterShield and swap it out for an extra basket.

- Take out the FOG collecting container, note how much FOG was taken out, and then pour the contents into a storage barrel.

- Reinstall the container onto the GreaseShield® after cleaning it with warm, soapy water and the wiper blade.

Upon installation, our engineers can provide staff training to all relevant staff plus every unit does come supplied with laminated posters showing the process. Alternatively, and more cost-effectively a video link showing the daily maintenance procedure is also available by clicking the following video.

You can contact EPAS Ltd through their contact form on the website, or email technical support at customerservice@epas-ltd.com, or by calling their customer service number +44 (0) 28 3083 3081.

EPAS Ltd offers various shipping options depending on your location. Standard delivery typically takes 3-5 business days, while express delivery options are available for faster shipping.

EPAS Ltd allows returns within 30 days of purchase, provided the products are in their original condition and packaging and subject to a restocking charge. Customers should contact technical support (customerservice@epas-ltd.com) to initiate a return.

Yes, all products EPAS Ltd sells come with a manufacturer’s warranty. The duration and terms of the warranty vary by product and are detailed on the individual product pages.

Yes, tracking is available upon request by the customer.

Yes, GreaseShield® products are designed to meet and exceed local and international regulations for grease management in commercial kitchens. Click here to know more about our certifications.

The website provides detailed product descriptions and specifications to help you choose the right product. Additionally, you can contact technical support for personalised recommendations. Please visit our products page for more details.

EPAS Ltd accepts all types of payments like, Direct debits, cheques, cash, bank transfers, and card payments except for AMEX.

You can sign up for the EPAS Ltd newsletter to receive updates on new products, special offers, and industry news directly to your inbox.

Yes, each product page on the website includes a downloadable user manual and installation guide. These guides provide step-by-step instructions for installation and maintenance. Please visit our products page for more details.

If you receive a damaged or defective product, contact EPAS Ltd technical support immediately. They will assist you with the return process and arrange a replacement or refund.

Downloadable Documents

GreaseShield® 3000-DW

1.Brochure

GreaseShield® 3000-F

1.Brochure

5.Operations Guide

GreaseShield® 4000-F

1.Brochure

5.Operations Guide