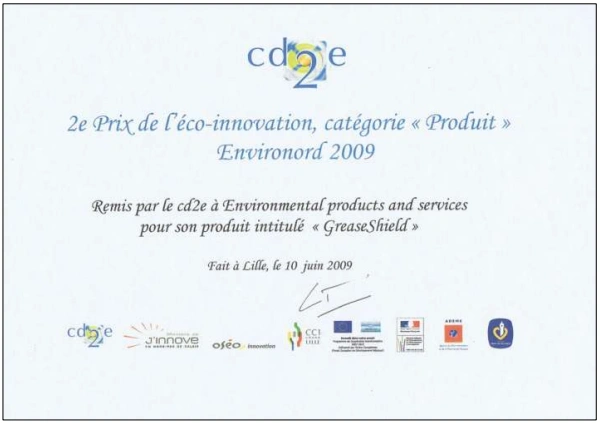

Our innovative award winning, globally certified products, deliver cost effective solutions for commercial kitchens.

GreaseShield® is a pro-active mechanical grease trap that operates in real time removing food waste and Fats, Oils & Grease.

FilterShield™ is the best solution for the separation and removal of solid food waste, coffee grinds and starch whilst enabling water to drain away.

SanicShield® is the ultimate odour management and disinfectant solution for both commercial purposes and household use.

Flexiplumb is a range of innovative and versatile rubber plumbing connections designed to fit around misaligned piping and mismatched pipe sizes.

Our GreaseShield® products, utilise waste thermal energy from pot sinks and dishwashers to facilitate the harvesting of FOGs and saturated fats,

being a renewable energy source and suitable for the production of biodiesel which produces up to 75% fewer lifecycle carbon emissions than

conventional diesel, significantly reducing greenhouse gas emissions.

We are proud to announce that EPAS Ltd has achieved PAS 2060 certification for carbon neutrality.

GreaseShield® is a truly unique oil and fats recovery system that replaces conventional grease traps and has been shown by our detailed life cycle analysis to have multiple life cycle benefits and parallel demonstrated cost savings. It avoids the regular vacuum truck extraction costs and instead replaces them with a potential income from sale of the grease, or at least low-to-zero cost recycling pickups. On top of that it takes heavy fats and oils out of the waste stream and recovers the resource, great low carbon climate and circular economy outcomes and great for the environment overall. There are none of the usual engineering impediments or major construction costs as they are typically a floor top installation. Why be limited by old practices?

David Baggs | CEO | Global GreenTag International Pty Ltd

GreaseShield® is a truly unique oil and fats recovery system that replaces conventional grease traps and has been shown by our detailed life cycle analysis to have multiple life cycle benefits and parallel demonstrated cost savings. It avoids the regular vacuum truck extraction costs and instead replaces them with a potential income from sale of the grease, or at least low-to-zero cost recycling pickups. On top of that it takes heavy fats and oils out of the waste stream and recovers the resource, great low carbon climate and circular economy outcomes and great for the environment overall. There are none of the usual engineering impediments or major construction costs as they are typically a floor top installation. Why be limited by old practices?

David Baggs | CEO | Global GreenTag International Pty Ltd

When I was first approached with a solution to my FOG problem, I was quite sceptical, given the level of technology employed and the cost of a GreaseShield® to replace my existing inefficient dosing system.

A few months later... what a difference it has made, I've not had a single problem caused by fats oils and grease in our waste water system.

I have never seen such an effective way of dealing with greasy water deposits and will gladly recommend the GreaseShield®.Danny O'Sullivan | Franchisee | McDonald's

I wanted to take a moment to express my sincere appreciation for the excellent service provided during the recent servicing of our grease trap. Barry was professional, efficient, and thorough in ensuring that our grease trap was cleaned and maintained to the highest standards. Having a properly functioning grease trap is essential for our business operations, and your expertise and attention to detail have not gone unnoticed. I am impressed with the level of care and dedication that Barry demonstrated throughout the servicing process.

Arpan Patel | Operational Manager | Imperial Lounge Croydon

We have been a customer of EPAS Ltd. For over three years and have consistently found their service to be excellent value for money. We plan to continue using their services in the future.

Bunsen

The GreaseShield® is working great and the staff are finding it easy keeping up the maintenance.

Wendy's Fish & Chips