Description

The GreaseShield® Range cleans wastewater by separating and recovering fats, oils, and greases (FOGs) using patented technology and inherent waste thermal energy in the effluent. Suitable for restaurants, cafeterias, hotels, schools, hospitals, commercial buildings, food processing plants and any context that requires a grease trap. The products can prevent blockages in drains and protects pumping stations as significantly reducing the loading on wastewater treatment plants. Frequent pumping costs are eliminated. The unit produces recyclable FOGs that can be used to manufacture biodiesel or to replace other oil-stock feeds.

Approvals

ASME A112.14.3-2000 Testing of Grease Interceptors, ASME A112.14.4-2001 Grease Removal Devices, CSA B481.0-2012 Testing of Grease Interceptors, CSA B481.1-2012 Testing and Rating of Grease Interceptors using Lard, CSA B481.5-2012 Testing and Rating of Grease Interceptors Equipped with a Grease Removal Device & PDI G 101. UL Approved (File No: E361705). Machinery Directive 2006/42/EC and EMC directive 2004/108/EC.

Average Power Consumption

- Hour 15.1 Watts

Flow Rates

Passive PDI =2GPM/7.571 L/m. Pro Active= 1 L/S

Application

10 to 12 Steam Combi Ovens only. If sink units are plumbed in then fit a PF or F. Do not exceed the rated flows.

Functions & Features

- Anti-Flood Pump – To maintain normal water level + recalibration feature

- Water Connection – Water Solenoid WRAS approved (or similar approval)

- CIP Bar

- Pressure Switch & Air Sensor

Parts Supplied as Standard

- Vortex Flow Controller – Fitted as standard

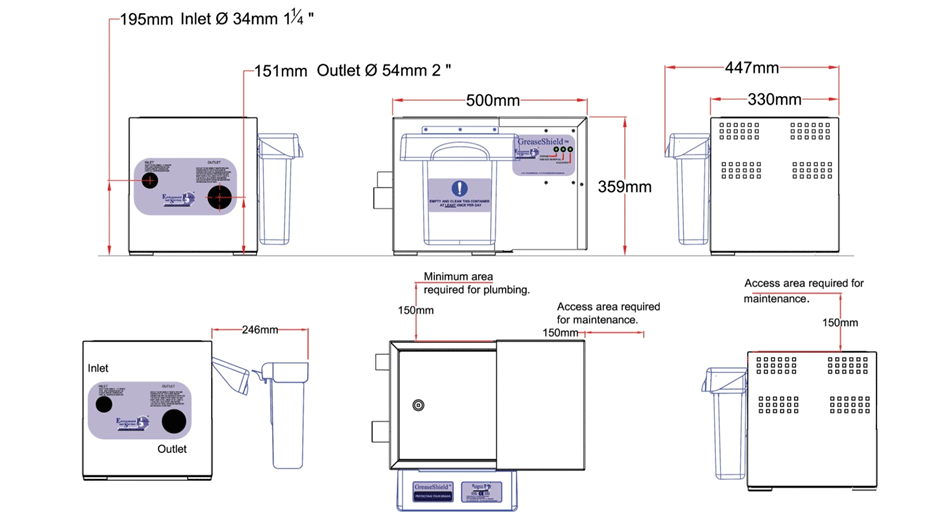

- FlexiPlumb® :- 34mm 90° bend (0635P02-34), 54mm 90° bend (0635P02-54)

- Blanking Cap (0635P10)

- Key(0509P86)

- ¾” Braided Hose For Hot Water (0214P15)

- Plumbing Pack see note

Default Program

(V5.4, V1.4) Start 7.00 Am, Stop 02.30 Am. FOG roller pulsing 5 Min On 5 min off. An anti-Flood and Recalibration cycle, when water intake is activated FOG roller is inhibited. Mains lead per country.

Installation Kit

- Stainless Steel 304 hygiene and service access adjustable stand essential for installation.

- IP56 Socket. Best Practice Management and Do’s and Don’ts, both laminated to be displayed on site.

- Daily Maintenance Logbook (12 months)

- Sampling Point

Ratings

EU

- Voltage: 240 Volts

- Frequency: 50Hz

- Current: 0.49Amps

US

- Voltage: 120 Volts

- Frequency: 60Hz

- Current: 0.98Amps